When it comes to acquiring new apps for 3D printing, there truly appears to be to be no restrict. Case in level, the Australian architectural agency BVN and the College of Technologies Sydney (UTS) have made Devices Reef 2, an air distribution method built employing 3D printing that, according to those dependable for the challenge, “breathes” like the skin of a frog. The exciting factor about this new remedy is that it has 90% fewer embodied carbon than a standard air conditioning system, demonstrating its dedication to environmental sustainability.

When it arrives to managing the air close to us, additive manufacturing also has its position to play. We have observed this on a lot of events, this sort of as with the AMS Mini and AMS Auto, the 3D printed products able of filtering and cleansing the air. Nevertheless, this time, we are not speaking about an invention that purifies the air, but a single that assists in the diffusion of air. All this in a far more sustainable way many thanks to the use of 3D printing.

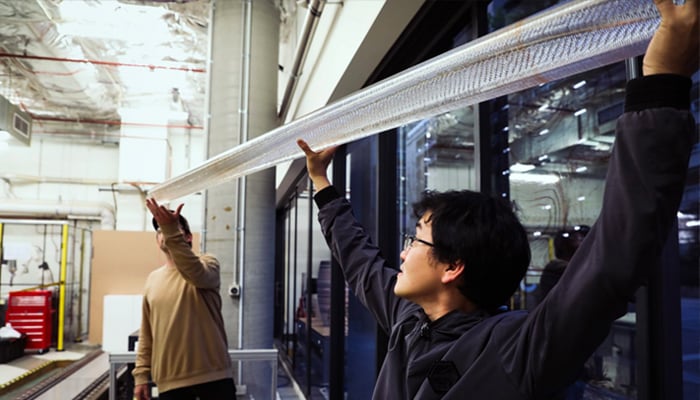

Task professionals with a person of the 3D printed areas of the Techniques Reef 2 (photograph credits: BVN / UTS)

3D Printing Was Employed to Make Systems Reef 2

The idea arose from the many shortcomings the researchers observed in conventional air conditioners. Air conditioning systems are typically made of sheet steel, with a substantial stage of embodied carbon and the use of considerably a lot more content than needed. They also squander vitality for the reason that they are structurally inefficient and difficult to switch immediately after installation. According to Ninotschka Titchkosky, co-executive director of BVN, producing has not transformed considerably since their creation in the 20th century. “At the moment, the programs that we have, they’re truly rigid, they are not significantly terrific for human ease and comfort, they are definitely expensive to transform and they definitely limit the way we want to occupy structures now in the 21st century, which is significantly more adaptive and agile,” she adds. Therefore was born Units Reef 2, or SR2, an air-conditioning system that integrates a pc-optimized shape and is produced with 3D printing.

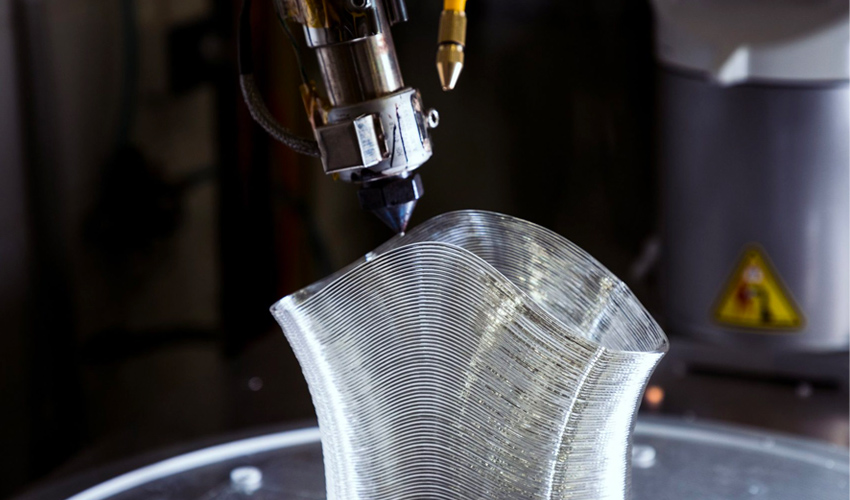

For this intent, recycled transparent plastic from hospitals was applied, crushed into pellets and fed into the 3D printing robot. This is coupled with generative design to make a beautiful answer that works by using the minimum sum of material achievable, even further demonstrating the project’s link to additive production and sustainability. In addition, it consumes a lot less working electrical power mainly because air flows easily about the organically branched tubes, avoiding corners to get stuck in. Moroever, by eliminating friction, the program is also lesser and thinner, which also final results in the use of significantly less content. In order to increase consumer ease and comfort, all those liable for the task had been impressed by frogs, which breathe via their pores and skin. As an alternative of utilizing ducts, they coated the Units Reef 2 with very small pores that blow air into the space down below.

Though this specimen is designed of clear substance, there is also the probability of printing it in shade or illuminating it to customize it. You can master much more about the process on their web-site Here or in the video below:

What do you feel of the 3D printed Units Reef 2? Let us know in a comment under or on our LinkedIn, Fb, and Twitter pages! Don’t forget about to indicator up for our no cost weekly Publication right here, the latest 3D printing news straight to your inbox! You can also discover all our films on our YouTube channel.

*Address Image Credits: BVN / UTS