A case examine describes how 3D printing can be utilized for automotive sculptures

The makes use of of 3D printing right now are properly established throughout trade, with the know-how routinely used for prototyping and remaining manufacturing. As increasingly more firms turn out to be conscious of the design freedom that 3D printing stimulates, and the flexibility of the know-how with regards to creating modern elements and elements, its adoption by a complete host of designers and producers is burgeoning.

Often, nevertheless, the usage of 3D printing has the power to cease you in your tracks, and such is the case when trying on the work undertaken by Jonny Ambrose (www.jonnyambrose.com). Ambrose makes vastly imaginative and tactile automotive sculptures, and 3D-printed elements have been on the coronary heart of his work (@jonnyambrose.autoart) for about 5 years.

“What makes my automotive sculptures work is the juxtaposition of conventional methods comparable to steam bending of wooden alongside the usage of ultra-up-to-date manufacturing processes comparable to CAD stable modelling and 3D printing,” Ambrose says. “Whereas beforehand I’d use milling when attempting to create lattice constructions, for instance, right now I exploit 3D printing that is ready to construct robust, light-weight constructions with geometries inconceivable to realize utilizing conventional manufacturing strategies.”

Ambrose has been working with 3DPRINTUK for numerous years since recognizing the methods wherein 3D printing could possibly be integrated into his work. Lattices are a great instance of how 3D printing opens up design prospects. What makes lattices distinctive is how they lay out supplies into design parts to type a great construction which might be made up of micro-architectures with a community of nodes and beams or struts. This format dramatically reduces weight whereas retaining structural integrity and giving a bigger diploma of management over sure traits. These interlinking parts can improve numerous areas of efficiency and use much less materials with out weakening the thing or compromising its integrity.

Giant Piece

The biggest one-piece lattice that Ambrose has produced was 40 cm lengthy. Consequently, the 3DPRINTUK group had to make use of all its know-how and understanding of 3D printing to accommodate the piece within the construct chamber, and guarantee its integrity as soon as constructed. This was all about orienting the half appropriately to get the most effective print definition, and ensuring that there have been no peripheral distortions on the extremities of the half.

For Ambrose, 3D printing has opened up a plethora of prospects for utilizing lattices in his work, however that’s not all that the know-how permits. He says, “Past the creation of lattices per se, I exploit 3D printing as a result of I just like the aesthetic of a few of the polished finishes. Additionally, it permits me to create extra intricate shapes and options, which might not be possible for me to do by hand. I discover the aesthetics of elements produced through selective laser sintering (SLS) or through Multi-Jet Fusion (MJF) extraordinarily enticing, and it enhances the woods, metals, and carbon fiber I exploit in lots of my works. For me, 3D printed elements are simply one other materials, however a cloth that brings new parts to my works that I can’t obtain through alternate means.”

Ambrose got here into contact with 3DPRINTUK at a commerce present when he was researching the state of the 3D printing sector and whether or not the know-how was one thing that he might incorporate into his work. Preliminary tasks tinkered round with the know-how usually constructing easy stable elements that might have been milled, however which by means of the usage of 3D printing and Autodesk’s Fusion 360 software program facilitated a comparatively easy and seamless workflow. Over time, Ambrose has used each the SLS and MJF processes by means of 3DPRINTUK, and in addition an array of post-processing applied sciences as he creates increasingly more intricate elements.

Utilizing Sharpening

“I exploit sprucing so as to add the required aesthetic to some elements. I discover that sprucing offers the elements produced a pleasant patina-like impact particularly on the black elements however to an extent on white elements as properly. Whereas every so often I exploit unpolished elements the place I require the virtually ‘sugar lump’ aesthetic, the place you may see the grain, it’s as a rule good to have management over the smoothness of elements, and I particularly like the virtually slate like look that may be achieved on polished black MJF elements,” Ambrose says.

Ambrose has been working with 3DPRINTUK since earlier than the corporate launched its add portal and ordering interface, which has extra just lately reworked the best way that he makes use of the know-how.

Straightforward to Use

Ambrose continues, “I’ve to say that I like the ordering interface and file add portal at 3DPRINTUK. Above all, its, easy-to-use. You merely drag and drop recordsdata, and you’ve got the power to trace every part and see how an order s progressing. Additionally, I can get into the system and edit half particulars if wanted. It simply works, and may be very properly thought out. It makes the shopper’s life simpler, and is clearly designed with the last word buyer expertise in thoughts. I like being answerable for my tasks and getting all the price and time-of-build suggestions routinely with out the intervention of gross sales folks. With the 3DPRINTUK system, I can tweak issues and assess the impact on value and construct time, and choose what I need quite than what I’m being bought.”

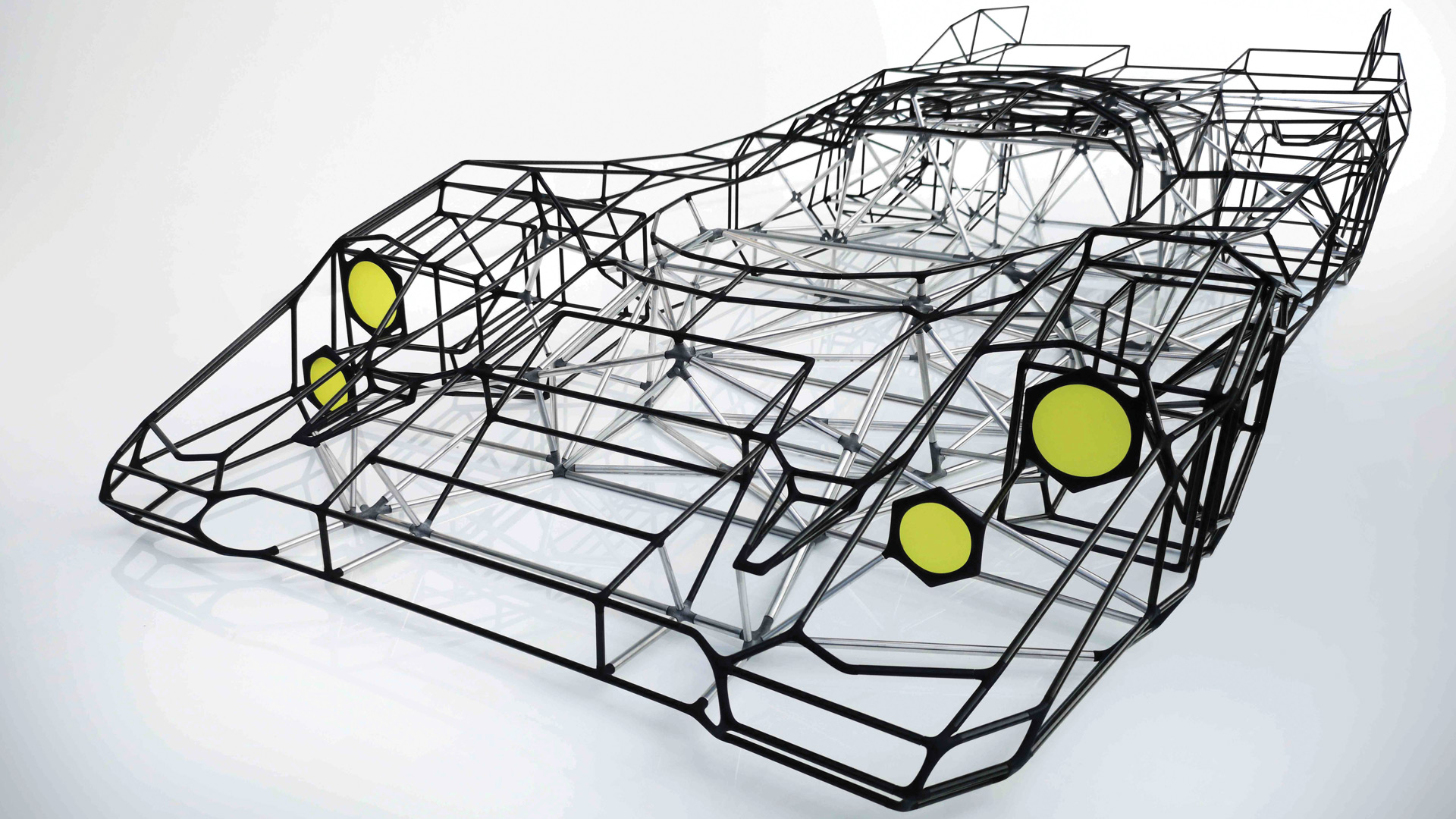

Certainly one of his current tasks is the Monster 917, a shocking half-sized sculpture impressed by the long-lasting Porsche 917k, which is a maze of tubular aluminium and carbon fiber linked by his personal 3D printed joints.

“The Monster 917 has taken loads of work, and the usage of 3D printing to provide the joints that maintain all of the tubes collectively exemplifies an ideal use of the know-how,” Ambrose says. “Making a sculpture like this can be a studying curve. Among the first 3D printed elements used within the chassis had been grey undyed MJF elements as they suited the aluminium tubes. I then used black polished joints when becoming a member of the carbon fiber. I knew 3DPRINTUK had the method versatility and post-processing applied sciences I wanted to accommodate these necessities. Every of the male lugs that maintain the tubes had been initially un-flanged, however because the design went on, I designed them to have a spring-like pressure which gripped the tube extra firmly. Design tweaks and modern prospects that might solely actually be realized by means of 3D printing.”

“The mix of functionality and experience at 3DPRINTUK is what works for me. Whereas the automated system is so good, it’s reassuring to know that behind the scenes is a group of specialists which might be at all times available to advise and optimize outcomes.”